|

|

This section eliminates the misleading, sales MIG gas mix information and MIG process confusion that for decades has surrounded global MIG weld gas selection.This web site was first established in 1998 by Ed Craig. Contact Ed (now Em) at ecraig@weldreality.com

MIG GAS MIX Information without Sales BS.

Five decades of marketing & sales misleading MIG gas information, and the common weld shop lack of MIG weld process control expertise, has for many in the weld weld industry, made a joke out of MIG Gas Mix selection.

Try asking the welders where you work, this fundamental MIG question.

Why is the MIG gas mix you are using the correct mix?.

Combine MIG gas confusion with MIG process control confusion.

When the MIG weld process was first utilized commercially in the 1950s, it was primarily used for welding aluminum, so MIG weld gas selection was simple, order straight argon, unless extra aluminum weld energy was required, then order an argon - helium mix. Later as the MIG process focus was on welding steels and alloy steels, at first straight CO2 was widely utilized, and then for MIG Short Circuit weld spatter reduction, it was found adding argon to the CO2 was beneficial and unfortunately gas companies came up with Argon - 25% CO2 that reduced spatter but was not suited to most Spray welds.

In the sixties, MIG gas research carried out by a few research facilities was revealing the influence of the MIG gas mix used, and especially the gas mix influence on the weld transfer mode capability, the weld parameter requirements for each weld mode, and the weld fusion and oxidation attained. However in the "why change the way we have always done it" weld industry, the worst MIG gas that could be used, straight CO2 and the Argon - 25% CO2 were the MIG gas of choice for most in the weld industry for 25 plus years, and still used by many 6o years later. However the irony was, it was not the weld industry that had the MIG experience that demanded superior MIG gas mixes that would enhance their MIG weld quality / productivity, it was the inexperienced industrial gas marketing departments and weld distributors that had the greatest influence on the MIG gas mixes being selected, and its been that way for decades.

HOW DO YOU KNOW IF THE WELD SHOP HAS HAD INEXPERIENCED WELD MANAGEMENT THAT LACKED THE ABILITY FOR MIG PROCESS OWNERSHIP AND RELIED ON SALESMEN FOR THE MIG GAS MIX THEY SELECTED?

If the weld shop is or has been using any of the following MIG gas mixes, its been a partner in the great gas con game that's gone on for more than five decades. The use of these gas mixes will have had either a detrimental impact on the MIG weld quality, weld productivity potential. Also note something that you would never had heard from the local gas suppliers, that if the correct gas mix had been selected they would have lowered the weld shops MIG gas costs and also the gas cylinders would have had more gas in the cylinders.

POOR MIG GAS CHOICES:

[b] Argon - 25% CO2.

[c] Any Argon - Oxygen Mix.

[d] Any Three Part, Argon - CO - Oxy gas mix for Steels.

[e] Any Three Part, Helium - Argon - CO2 mix for Stainless.

[f] Any Helium Argon mix for aluminum welds < 5/16 thick.

[g] Any Argon - Nitrogen mix for aluminum.

A STAGGERING STATEMENT THAT I CAN PROVE IN 60 MINUTES IN ANY WELD SHOP. "IT'S ALMOST 2020, & SIXTY PLUS YEARS AFTER THE INTRODUCTION OF MIG WHICH IS THE WORLDS MOST WIDELY USED ARC WELD PROCESS, AND YET MOST OF GLOBAL WELD SHOPS ARE IGNORANT ON THE SUBJECT OF THE MIG GAS MIX INFLUENCE ON THE WELDS THAT THEY DAILY PRODUCE."The weld reality is weld shops will bot make correct MIG gas selection without MIG weld process expertise. Is that expertise part of your weld shop?

A simple MIG weld question for any weld shop would be: If welders while using MIG Spray to weld 1/4 (6 mm) steel parts, decides to change their gas mix from an Argon - 20 % CO2 mix, to an Argon - 5% Oxy mix, they would have to change what, and why? And what will happen to the weld fusion? Anyone that has an opinion on MIG welds and that includes AWS weld inspectors, should understand, the required MIG weld process controls - best practice requirements, as well as the influence on the welds of the MIG weld gas & wire consumables selected.

How is your MIG weld gas expertise? Why not try my MIG Weld Gas Test: If you would like to learn all about gas mixes and MIG weld process control - best practice requirements, you may wish consider my "MIG and flux cored process controls - best weld practice" self teaching / training Resources.

IN THE 70s AND 80s, THE MAJOR INDUSTRIAL GAS COMPANIES TOOK NOTICE OF THE RAPID, GLOBAL MIG WELD PROCESS GROWTH ON STEELS AND ALLOY STEEL APPLICATIONS, AND THEY SAW A GREAT OPPORTUNITY FOR A DRAMATIC INCREASE IN THEIR INDUSTRAIL GAS SALES THROUGH THEIR WELD DISTRIBUTORS. ALL THE MAJOR GAS COMPANIES STARTED AGGRESIVE MIG MIX MARKETING CAMPAIGNS THAT WERE NOT DEVELOPED TO IMPROVE MIG WELDS BUT WERE DEVELOPED TO ATTAIN NEW GAS BUSINESS AND INCREASE THEIR INDUSTRIAL GAS MARGINS.

THE GAS COMPANIES & DISTRIBUTORS SET OUT TO CONVERT WELD SHOPS FROM USING CO2 OR THE OTHER POOR COMMON ARGON - 25% CO2 MIX, AND WITHIN A FEW YEARS, APPROX. 40 DIFFERNT GAS MIXES WERE AVAILABLE FOR SALE IN NORTH AMERICA. (APPROX. SIX ARE NECESSARY FOR ALL MIG WELDS).

THE MIG GAS MIX IGNORANCE, CONFUSION & CON GAME HAS GONE ON FOR APPROX. 60 YEARS. THANKS TO THE FAILURE OF THE GLOBAL WELD INDUSTRY TO EDUCATE & TRAIN WELD DECISION MAKERS ON MIG WELD PROCESS CONTROLS - BEST WELD PRACTICES, IN MOST (NOT ALL) 2020 GLOBAL WELD SHOPS, IT WOULD NOT BE DIFFICULT TO FIND WELD PERSONNEL WAITING TO TRY ANOTHER SO CALLED UNIQUE SPECIAL MIG GAS MIX, A MIX THAT THE WELD SALES REP WILL PROMISE TO BE THE REAL SOLUTION FOR THEIR DAILY MIG WELD PROCESS ISSUES.

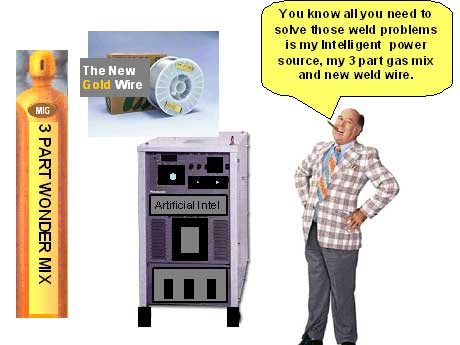

One industrial gas companies stupid approach

to show how special their MIG weld gases are.

SO WHILE APPROX. FORTY MIG GAS MIXES ARE AVAILABLE FOR NORTH AMERICAN WELD SHOPS, REMEMBER THAT MOST WELD SHOP PERSONELL WONT BE AWARE OF THE MIG GAS REQUIREMENTS OR THE MIG PROCESS CONTROL REQUIREMENTS FOR SPRAY TRANSFER. MOST WELD SHOPS WILL HAVE WELDERS PLAYING AROUND WITH THEIR MIG OR FLUX CORED WELD CONTROLS. WITH THIS IN MIND, ITS EASY TO UNDERSTAND THAT WHEN THE SAME WELD SHOPS ARE SERVED BY PROCESS IGNORANT INDUSTRIAL GAS PROVIDERS, WHY THE MIG GAS MIX BOVINE FECAL MATTER HAS BECOME AN IMBEDDED PART OF WHAT SHOULD BE A WELL ENGINEERED, CONTROLLED, TECHNICAL INDUSTRY.

THIS SITE IS NAMED WELD REALITY FOR A REASON. I HOPE YOU APPRECIATE THAT REALITY, AND USE PROCESS CONTROL EXPERTISE TO HELP BRING SOME RESPECT BACK INTO THIS IMPORTANT INDUSTRY.

MIG GAS FACT: Whenever you see any "three" or four part gas mix for MIG welding carbon or any alloy steels, you know the industrial gas manufacturing marketing team and distributor sales team are doing the thing they have done for six decades, with the introduction of another, useless, over priced MIG gas mix.

Note: For any company wasting money on purchasing useless three part gas mixes, remember it would take me less than 2 hours at any global facility to prove that the three part MIG gas mix purchased has no justification.

MIG GAS FACT: If you worked for a company that in the last six decades that was using argon - 25% CO2 or straight CO2 for steel and alloy steel welds, you were working for a weld shop management / supervision that knows little about MIG welding and they likely would have been better suited to managing a donut shop.MIG gas mix selection has always been an essential component in attaining optimum MIG weld quality and productivity. If in 1960 or 2020, weld shop management and supervision did not understand the real world MIG weld restrictions, weld requirements and weld benefits of the MIG weld gas mix that their company selected, then its likely the front office management would have turned to a salesman for MIG gas advice. Salesman who were guided by the misinformation and BS provided by their industrial gas supplier.

MIG GAS FACT: For decades the worlds leading MIG weld equipment manufactures such as Lincoln, Miller and ESAB also followed the industrial gas companies marketing BS information on MIG gas mix recommendations. So when Lincoln - Miller - Hobart and ESAB provides MIG gas nonsense, this simply added to the global MIG gas process misinformation and confusion which sadly for sixty plus years has been imbedded throughout most of the global MIG weld industry.

MIG GAS REALITY: In a thirty minute practical weld demonstration, I could as anyone should be able to do with MIG weld process control expertise, demonstrate that all the over priced, global three part gas mixes being used for MIG welds on carbon steels, stainless and alloy applications, provide no practical MIG weld quality, metallurgical or weld productivity benefits than what can be attained with one of my MIG mixes below and weld process control expertise.

MIG GAS AND WELD SPECIFICATIONS REALITY: So your company is working to some AWS specification recommendations and actually believes all that they read. Its important for those that like to deal with the real world, to be aware with those AWS weld specs, the source of their weld specification data.

In the decades when most of the MIG (and flux cored) weld specifications were written, unfortunately many of the AWS weld process and consumable specification committee members were made up of weld consumable & weld equipment "MARKETING - SALES PERSONNEL" With the sale influence in mind, it should be no surprise that some of these individuals would not only add their MIG process control ignorance to the weld specifications being produced, but also add their very product bias gas recommendations into specifications, that unfortunately so many in the global industry take seriously.2019: Some of you may want to know my MIG weld gas expertise is. I was one of the key writers that wrote the American Weld Society, MIG Shielding Gas Specification. AWS A5.32. Over the years, a good portion of my efforts at developing those AWS 5.32 MIG gas specification, was unfortunately trying to minimize the extensive sales hype and BS that some of the MIG gas committee members at the meetings wanted to introduce into this important subject. Also at one time or another, in North America I worked in the roles of Weld Training / Product Manager, with Linde, Liquid Air, Air Gas, AGA, and Liquid Carbonic. And I have over 50 years of MIG process control expertise, an expertise that I have applied at fixing MIG weld issues in over a 1000 companies in 13 countries.

By the way, you might want to know why I sound so frustrated and pissed off with the weld industry on this important weld process subject. It's because I've written over 30 articles and three books on the MIG subject, and most important to overcome the general MIG process control ignorance, I simplified the subject and provided the MIG weld process controls - best practice educational resources on MIG - Flux Cored - Advanced TIG & TIP TIG, subjects that few in the weld industry seem to have an interest in.

MIG GAS CONFUSION HAS HELPED CREATE APPROX. 40 UNNECESSARY MIG GAS MIXES, AND ALSO GREATLY ADDED TO THE INDUSTRIAL GAS COMPANIES AND DISTRIBUTORS GAS SALES AND PROFITS:

With over 40 different MIG gas mixes, the weld reality is the weld industry needs no more than 6 MIG gas mixes, and the unfortunate approx. seven decades of global, MIG gas mix lies, ignorance with the gas supplier & weld shop customer MIG process confusion, has been of no benefit to weld shops, but highly beneficial for the global industrial gas companies and their distributors gas sales and profit margins.

MIG weld gas ignorance, enables weld gas profits

So to increase our MIG gas profit margins & help us get into a coemptive gas accounts,

I've come up with a new three part gas mix for steel MIG welds, and called it "BS" gas.

Note: Some of the gas information on this web site is taken from my MIG and flux cored weld process controls - Best Weld Practice, Self Teaching - Training Resources.

WELD SHOP MIG PROCESS IGNORANCE HAS GONE A LONG WAY TO ENABLING THE GAS MARKETING BS:

When gas company executives promote their commodity gas products in an industry where MIG weld process and consumable ignorance / confusion is often the norm, the gas company marketing executives are provided with an open door to provide extensive MIG gas mix bovine fecal matter.

Please note that the majority of gas company executives involved with the introduction of MIG gas mix sales simply do not have a clue about the MIG weld process, or about the weld energy and reactivity concerns of a MIG gas selected. The weld reality is that all most gas company executives typically care about, is will the gas mix introduced increase their gas mix prices and margins and increase their their weld shop customer base.

2019: ITS NOT JUST THE GLOBAL GAS COMPANIES WHO TYPICALLY DONT HAVE A CLUE ABOUT MIG WELDING GASES, ITS ALSO MOST OF THE WELD DISTRIBUTORS, THE MAJOR MIG EQUIPMENT & WIRE MANUFACTURES, ALL OF WHICH FOR SIX DECADES HAVE ADDED TO THE MIG GAS MYTHS AND CONFUSION FOUND FOR DECADES IN GLOBAL WELD SHOPS.EDUCATIONAL & TRAINING FACILITY WELD EDUCATION FAILURE.

ITS ALSO A SAD REALITY, THAT THE GLOBAL FACILIIES THAT TRAIN WELD ENGINEERS AND WELD PERSONNEL ON THE SUBJECT OF MIG AND FLUX CORED WELDING, HAVE FOR DECADES NOT BEEN AWARE OF THE IMPORTANCE OF WELD PROCESS CONTROLS & BEST WELD PRACTICES. THIS ALSO HAS ENABLED THE CONTINUATION OF THE COMMON MIG WELD GAS MYTHS, PROCESS CONFUSION, AND IS THE REASON WELD PERSONNEL OFTEN PLAY AROUND WITH TWO SIMPLE MIG WELD CONTROLS.

Relying on a salesman, for weld advice has been

the global Achilles heel of most weld shops that use MIG.

-

If the welds shops bought into the nonsense that we provided them about our new 3 part MIG gas for their steel welds, I cant wait to see their reactions when we introduce our new four part mix?

THE SUCESS OF MIG TRI - MIX SALES FOR COMMON STEELS ARE AN INDICATION OF THE LACK OF MIG WELD PROCESS EXPERTISE THAT PREVAILS IN THE WELD INDUSTRY. LETS START OUT WITH THE MIG HELIUM TRIMIX GAS THAT WAS DEVELOPED BY UNION CARBIDE IN THE 1960s. THIS GLOBAL GAS MIX SOLD FOR STAINLESS GAUGE WELDS IS SIMPLY A MIG GAS MIX PRODUCT THATS NEVER BEEN NECESSARY.

TRI - MIX: 90% HELIUM - 7. 5% ARGON - 2.5% CO2:

ALWAYS A WELD FACT: The weld industry would be better served learning MIG weld process controls and best weld practice expertise, instead of getting frequent weld advice from a weld distributor sales rep who likely has never worked in, or managed a weld shop.

90% HELIUM TRI MIX GAS FACT: Since the 1960s and still as I write this in 2019, thanks to Union Carbide, (Linde - Praxair), many North American and European weld shops have purchased this Helium - Argon CO2 tri-mix gas for MIG welds on stainless gage applications. For the majority of gauge stainless applications, the helium tri-mix was in reality the worst possible gas mix choice for most gauge stainless steels.

Note: The helium tri-mix, was one of the few honest attempts by an industrial gas supplier at MIG weld gas research, however in this case the MIG gas researches simply missed the boat.

Note: Most of the MIG gas research that followed the helium trimix was in reality sponsored by gas companies and usually product biased and lacking in MIG process reality.

STAINLESS MIG GAS MIXES & WELD REALITY. With most MIG Stainless gage applications 14 gauge and thinner, the four most primary MIG weld concerns for weld shops when welding the THIN GAUGE stainless parts would be;

[1] MIG weld burn through, (rework).

[2] MIG weld part distortion, (rework).

[3] MIG weld oxidation. (cleaning).

Note: Spatter is a concern, but this typically results from lack of MIG weld process control expertise.

AND THE COMMON DENOMINATOR OF THE ABOVE STAINLESS THIN GAUGE WELD ISSUES, 1 - 2 - 3 WOULD BE?

I don't believe that it should take much to figure out with the above three primary MIG stainless gauge weld issues, that the common denominator with the issues, would be they are all "WELD HEAT RELATED" .

HELIUM TRI-MIX, A RIDICULOUS GAS MIX CHOICE FOR SIXTY YEARS: The Carbide MIG gas solution for stainless gage welds for weld shops that often were dealing with weld heat related issues, was to promote and sell the worlds "HOTTEST MIG gas Tri-mix". The Tri-mix containing 90% helium - 7.5% Argon - 2.5% CO2 requires the highest MIG weld voltages, which for 60 years has ensured more energy into the thin MIG welds than any of the other available MIG gas mix.

Note: In the 1980s, while working for AGA as the USA corporate weld training manager, and twenty plus years after the Carbide introduction of Helium tri-mix, I was in a position to do MIG gas research and determined to do my best to try and reduce the stainless and carbon steels, three part MIG gas mix BS data which was imbedded in many of the global weld shops that were MIG welding carbon steels, alloy steels and alloys.

REAL WORLD STAINLESS MIG WELD GAS REQUIREMENTS: With my evaluation of a logical MIG gas mix for stainless gauge welds, I set to MIG welding 20 - 18 - 16 - 14 - 12 and 10 gauge stainless MIG weld samples that included butts - fillets & lap welds.

Setting optimum MIG parameters for any weld to me is like breathing. So using the best possible short circuit (SC) weld parameters, and 0.035 (1mm) stainless wire, (the best MIG wire size diameter suited to all SC welds), I evaluated several of the typical MIG gas mixes including argon - oxy, and the Helium - Argon - CO2, tri-mix.

My weld focus with the gas research was on the weld energy required and being delivered, and also on the gas oxidation reactivity. And to make a long story short which for me on the subject of welds has always been difficult, after a few days of testing the stainless gases, in the 1980s, I developed and introduced a new Stainless TWO PART MIG Gas Mix. This mix would provide real world MIG weld solutions for all Stainless, Duplex & most Alloy steels, MIG short circuit, spray and pulsed applications. The honest gas mix that I came up with was, 98% Argon - 2% CO2.

ED - EMS, GAS MIX FOR STAINLESS. 98% ARGON - 2% CO2.

MY ARGON - 2% CO2 MIX: To overcome the weld heat issues on most thin stainless gauge welds, and to provide low oxidation and lowest weld distortion potential with the higher energy pulsed and spray modes, in contrast to the Helium Tri-mix, Ed now Em, developed the practical and much cost effective, two part MIG gas mix. 98% Ar - 2% CO2. If you are using my gas mix for your welds on stainless and alloy steel welds, there is no need to send money, but a note of thanks, or better still a case of wine would be considered acceptable.

Note: Whenever you see 1/2% included in any MIG gas mix, you know the BS has reached its peak, and the gas marketing and sales personnel are salivating.

MORE DETAILS ON WHY THAT HELIUM TRI MIX GAS WAS DEVELOPED IN THE FIRST PLACE.

Long ago, in a time when stupid people were not allowed to run the White House and a longtime before propaganda shows like Fox News and about 25 years before the introduction of the Pulsed MIG process, Carbide / Linde, who by the way were the most highly reputable global leader in producing everything related to the MIG process. This no BS company established what they thought was an important MIG gas research project focussed on the influence of the MIG Gas Mixes selected when using on MIG Short Circuit, gauge stainless welds.

The Carbide gas research engineers, examined the influence of Helium on the MIG short circuit weld transfer mode. From their MIG stainless weld gas research, they developed a Helium Tri-mix containing, 90% He - 7.5% Ar - 2.5% CO2. The researches saw the Helium Tri-mix as a solution for short circuit MIG welds on stainless gauge applications. What most people in global weld shops, would not have been aware of was that the Carbide researchers who were testing the Helium Tri-mix, saw the MIG Short Circuit weld fluidity benefits mostly on THICK GAUGE STAINLESS PARTS, > 0.100.

As most of us around stainless MIG Short Circuit welds, (SC = arc on - arc off) are aware, stainless with its high nickel and chrome content promotes a slower weld solidification rate, resulting in welds that are more sluggish than the MIG short circuit welds made on the same thickness carbon steels.

With the low weld voltages & current that's utilized with Short Circuit (SC) welds. The SC welds made on the thicker gauge applications, (> 14 gauge) would often be convex welds, with evident fast freeze lines and scalloped weld edges, weld effects that can result in poor weld fusion.

The extra weld energy that helium provided for the "thicker gauge" SC stainless welds, came from the higher SC weld voltage requirements necessary for the helium molecular gas dissociation. In contrast to none helium MIG mixes used on MIG argon - CO2 or argon - oxy mix short circuit welds, with the helium tri-mix, 1.5 to 3 extra weld volts would be typical.

From the Carbide gas research perspective, the higher energy helium mix was therefore viewed as a solution for MIG short circuit stainless > 12 gauge welds, the thicker gauge was what they tested the tri-mix gas on.SO AFTER APPROX. 60 YEARS OF HELIUM TRI-MIX GAS NONESENSE, HERE ARE THE HELIUM TRI-MIX MIG WELD FACTS THAT I FIRST WROTE ABOUT 30 YEARS AGO:

In the Carbide / Linde gas article that I read decades ago, the weld reality of their Helium Tri-mix short circuit gas research, was that the common MIG spray transfer mode, the use of smaller wire diameters, and MIG weld process control options were not included as solutions for the MIG welds made on the thick gauge stainless welds.

As with many of the global weld gas research programs that followed, the Linde MIG Tri-gas mix research which was supposed to provide the best possible solutions for MIG welds on "gauge stainless applications", was from a weld process very incomplete. And therefore the Carbide Tri-mix gas research result as applied to stainless MIG Short Circuit welds, was both lacking and misleading. This gas mix was then introduced to an industry that knew almost nothing about MIG gas mixes and even less about MIG process controls. The folklore began and those that produced and supplied helium rubbed their hands.

Knowing Carbide well, after all I was their Weld Training Manager for Western Canada, I don't believe their was any intention from the researches to mislead the global MIG weld industry, that unfortunately came later from all of the industrial gas, MIG weld equipment and MIG consumable companies. I do however believe that the gas researchers may have had limited understanding of the common weld shop stainless gauge applications, and also may have had limited MIG weld process controls and best weld practice expertise that could have been applied to the stainless MIG gauge applications. A lack of weld shop application expertise is not uncommon with research individuals, and as for MIG weld process control expertise, remember this was the 1960s and the sad reality is, that the lack of MIG weld process control expertise is in 2019 still the norm.

WHEN AN INDUSTRY SUCH AS THE WELD INDUSTRY BLINDLY BUYS INTO A GAS SALES ADVICE & BS WITHOUT CHECKING THE NEED OR THE EFFECTIVENESS OF THE PRODUCTS BEING RECOMMENDED AND PURCHASED, WHAT DOES THAT SAY IN GENERAL ABOUT THE EXPERTISE OF THAT INDUSTRY?

Note: In the 1960s, with the rapid growth of the new MIG process for steels, Carbide, then Linde was the industry MIG weld gas, weld wires & MIG weld equipment leader. In general this company provided excellent MIG, flux Cored and SAW data with minimum BS. However in this time period, when global MIG equipment sales were explosive, the weld shops then as they still do 60 years later, showed little interest or were simply not aware of the benefits attained from MIG weld process controls - best weld practice expertise.

THE WELD SALES INFLUENCE ON THIS TECHNICAL INDUSTRY HAS BEEN SIMPLY CORROSIVE: Unfortunately over the decades it became common in the global weld industry, that if you did not know something in the weld shop about the weld process being used, the hands off front personnel would ask a weld sales person for advice. The sales rep working for the distributor would in many instances have a degree in History or Liberal Arts, and had never run a weld shop. The reliance by the weld industry on inexperienced sales reps became entrenched in the late 1970s and 1980s, and the MIG weld gas and MIG / FCA weld wire product marketing / sales NONESENSE rapidly immersed the weld industry, knee deep in MIG weld info. BS, and resulting MIG weld process confusion is prevalent around the globe in 2019.

SO THE HELIUM GAS MIX PROVED TO BE A GOOD SALES TOOL FOR AN INDUSTRIAL GAS GIANT: The new Helium TRI-MIX introduced in the 1960s, was seen by Carbide industrial gas marketing executives as a great sales tool to enable their numerous distributors access into the competitive global MIG welding accounts that were welding stainless. You have to keep in mind, that when a sales rep. requests that a weld shop test a new MIG or FCA weld gas or weld wire, that in general this is the blind leading the blind, and I apologize to the blind.

Remember at the time of the Tri-mix gas introduction, and ironically still 60 years later, the majority of MIG weld personnel "play around" with their two MIG controls, and also lets not forget that most MIG welders often did not know what short circuit or spray transfer was. There is little logic asking weld personnel who play around with with weld controls, to test anything related to that process. With this common customer base, if a reputable company such as Carbide, Linde or today Praxair, states that the Helium Tri-MIX was the best gas mix for welding stainless gauge welds, who the hell was going to argue?

The Helium Tri Mix research and gas recommendation for stainless short circuit welds had a dramatic impact on the global MIG weld industry, and the reality set in for Carbide and for the other major gas company executives, that the introduction of a so called unique three, or even two part MIG gas mix, would be a good marketing tool to attain not only new competitive weld gas business, but was also a great tool to go after the competitive MIG weld equipment, MIG and flux cored weld wires & also the oxy. fuel cutting products business.

For seven decades, most of the global weld equipment and consumable manufactures & distributors have welcomed the introduction of new, weld gas mixes, weld wires and bells and whistles MIG equipment which would enable the distributor sales reps access to competitive accounts.

I HAVE HEARD MORE REALITY COME OUT OF THE MOUTH OF A USED CAR SALESMAN.

When weld shops have to rely on a salesman for MIG process advice with a 70 year old, little changed, two controls MIG process, you have to expect gas BS, and also what does that say about the weld expertise calibre of the managers, engineers and supervisors that are supposed to be running the welds shops?

CONCLUSION ON THE MIG HELIUM TRI-MIX GAS: In the 1960s or today in 2019, the traditional CV MIG equipment enables both MIG Short Circuit and MIG Spray Transfer. However those Union Carbide / Linde Tri-mix gas researchers when doing the MIG weld research on the stainless gauge welds, were focussed on the weld issues that were occurring with MIG Short Circuit welds on the THICKER > 0.080 stainless gauge parts.

Unfortunately the Carbide / Linde gas research personnel seemed unaware of the capability of utilizing low end Spray transfer parameters with an 0.035 MIG wire for stainless welds . This is an excellent weld approach for most stainless gauge MIG welds on parts >0.080.

With the higher weld deposition MIG spray mode, and using the common 0.035 (1 mm) stainless MIG wire at the "spray start parameters" the MIG welds in contrast to short circuit would "allow the higher energy welds that enabled higher weld speeds". The increased spray weld speeds dramatically decrease weld heat related concerns, and also the spray welds enabled improved weld fusion, decreased porosity and something every weld shop should desire, a dramatic increase the weld shop productivity.SOME PULSED MIG WELD REALITY FACTS:

2019: Few weld shop personnel are aware that the majority of the Pulsed MIG equipment introduced into global weld shops for at least two decades, provided no, or very limited steels or alloy steels MIG weld benefits, it did however add to the weld equipment mfg. profits and to global weld shop confusion. However also in this this time period pulsed MIG units have provided real world weld benefits on aluminum parts less than 1/4, < 6mm. As Pulsed also provided lower weld heat than spray welds, sometimes this process benefited heat sensitive stainless and alloy steel applications.

Note: Pulsed is often not necessary on many aluminum MIG applications > 1/4, (> 6 mm), as MIG Spray transfer can enable superior aluminum weld fusion, lower weld porosity, and provide increased stability with higher weld deposition rates.

2019.. FINALLY WE HAVE PULSED EQUIPMENT THAT CAN ELIMINATE THE USE OF SHORT CIRCUIT: In 2019, if you get your hands on an OTC Daihen pulsed MIG unit, which from my perspective is the best performing and most cost effective pulsed unit available, you would find that in using their Pulsed mode in its low parameter range, that there is no longer a need for Short Circuit welds for any thin gauge metals. Also Pulsed in contrast to Spray weld on steels, alloys and alloy steels >1/4, (> 6 mm) can offer lower weld heat, (less distortion), but as I have said for three decades with pulsed MIG, always remember with parts > 3/16 thick to produce weld section MACROS and check the weld fusion.

2019" MANY TIMES WELD PERSONEL ASK, WOULD I PURCHASE A PULSED MIG UNIT? AFTER EVALUATING GLOBAL PULSED MIG EQUIP. FOR MORE THAN 30 YEARS, IF MY WELD SHOP WAS WELDING THIN ALUMINUM (< 1/4 / < 6mm), I WOULD PURCHASE A PULSED UNIT. HOWEVER IF MY WELD SHOP WAS MOSTLY WELDING STEELS & ALLOY STEELS, FOR THESE WELD CELLS, I WOULD NOT PAY THE EXTRA DOLLARS REQUIRED TO PURCHASE PULSED MIG EQUIPMENT.

MY ARGON - 2% CO2 MIX IS SUITED TO THIN & THICK STAINLESS APPLICATIONS WITH ALL MIG TRANSFER MODES:

For the weld shop, my Argon - 2% CO2 MIG mix enables lower weld voltages than required with the Helium Tri mixes making this gas mix better suited to welding the common "thin gauge stainless parts such as 14 - 16 - 18 gauge, using an 0.035 wire. As for MIG welds on thicker gauge stainless or alloy steel parts, the weld shop with the Argon - 2% CO2 mix, should again with the 0.035 (1 mm) MIG wire, set the low end Spray Transfer or with pulsed and 0.045 wires set moderate parameters. If the welders don't know what the low end of spray parameters are or moderate pulsed parameters are, well you know the process training solution to that.IF WE CAME FACE TO FACE, I WOULD BET YOU THAT THE WELD PERSONNEL IN THE SHOP WHERE YOU WORK, DO NOT KNOW WHAT THE SPRAY START POINT PARAMETERS ARE WITH A STAINLESS MIG WELD USING EITHER AN 0.035 or 0.045, (1 - 1.2 mm) WIRE?

For my MIG and flux cored weld process controls - best weld practice self teaching - training resources click here.WITH MY ARGON 2% CO2 mix, and using the traditional low cost, durable CV MIG equipment that's changed little in 70 years, and knowing when to switch from Short circuit to Spray parameters with the common 035 - 045 wires, with the argon - 2% CO2 mix, you end up with a low cost mix, and having no oxygen in this mix, the stainless argon CO2 welds would have lower weld oxidation potential, enable easier weld cleaning with less porosity, benefits by the way that apply to most alloys and alloy steels applications.

IT TOOK DECADES, BUT FINALLY WE HAVE

PULSED MIG EQUIPMENT THAT BENEFITS STEELS.

Takes awhile to figure out the wide array of weld controls, but dollar for dollar,

and for more than a decade, this has been the best performing pulsed MIG unit.

PULSED MIG STAINLESS. It took approx. 30 years of pulsed MIG weld equipment development, and finally some pulsed MIG equipment such as built by OTC can actually provide some real weld benefits for both thin and thick stainless steel welds.

SO WITH THE RIGHT PULSED MIG EQUIPMENT, SHORT CIRCUIT WHILE STILL EFFECTIVE MAY ALSO NOT BE NECESSARY. In 2019, with some pulsed MIG equipment as shown above, the weld reality is you would no longer need to set the short circuit weld transfer mode, so you have a single weld mode capable of welding both thin and thick parts. Qualified weld decision makers would also be aware that on many this welds the traditional short circuit mode with it's arc on - arc off capability may be better suited, and spray usually enables superior weld fusion and less porosity than the Pulsed mode.

Note: Pulsed MIG power sources will typically also offer Spray and Short Circuit transfer modes. What most weld shops will not be aware is that these two weld modes available in the inverter pulsed units will be inferior to the short circ. and spray modes available on traditional CV units.Note: If weld shops are welding stainless, inconel, or duplex or any all position "code quality" steel welds, and not using the TIP TIG process, those weld shops are simply stuck in the 20th. Century.

Remember it does not matter what the MIG weld power source is or the weld mode selected, MIG welds will rarely be optimized if MIG weld process controls - best weld practice expertise is lacking. Ems Process Control data here.

ITS AN IRONIC POINT WORTH NOTING, THAT WITH THE NUMEROUS WELD SHOPS RELIANCE ON WELD DISTRIBUTORS AND WELD EQUIPMENT & CONSUMABLE MFG. REPS FOR MIG WELD GAS AND PROCESS ADVICE, THAT FOR MORE THAN SIX DECADES, MOST OF THE WELD DISTRIBUTORS AND REPS WERE ONLY AWARE OF THE MIG GAS MYTHS AND THE BOVINE FECAL MATTER THAT THE GAS COMPANIES FED THEM:

MANUAL OR ROBOTS, NO NEED FOR THIS NONESENSE:

I HOPE YOU DO NOT HAVE TO ASK LINCOLN, MILLER, HOBART OR ESAB FOR MIG GAS ADVICE, or for that matter any advice about MIG welding. Over the three plus decades that I evaluated the mostly poor performing Pulsed MIG equipment, especially from these MIG equip. manufactures, it was interesting for me to watch these MIG equipment manufactures while slowly trying to make electronic improvements with their erratic and poor performing pulsed MIG units, that they would also be recommending MIG gas mixes to be used with their pulsed equipment, and the mixes they recommended were often a poor choice and usually based on the gas misinformation and BS provided by the major industrial gas suppliers.

Lets nip back to the 1980s when I was with AGA, and developing my 98% argon - 2% CO2 MIG mix:

With most Swedes being civilized, the Swedish company AGA Cleveland was a great company to work for, and they gave me much freedom to do any MIG gas research. Within a few weeks of doing stainless MIG weld gas tests, I found the weld issues and resolution for the weld issues being caused by both the helium tri-mix on gauge stainless welds and also by the argon oxygen mixes which were often used for stainless MIG spray welds > 1/8.

MY MIG GAS - APPLICATION LOGIC: The first logical step was to decide where short circuit should be used on gauge parts, what was the thickness max, before changing the weld transfer mode to spray? To deal with the common weld heat issues on gauge stainless parts < 12 gauge, I simply took that costly helium out of the helium tri-mix, which left me with an Argon - 2.5% CO2. I knew that 0.5% CO2 in any mix makes the mix sound complex and fills a gas marketing function, however 0.5% of any industrial gas makes minimal difference to any MIG weld. So I ended up with a stainless MIG gas mix that contained Argon - 2% CO2. By the way I was well aware in the 1980s that with stainless MIG gas mixes its beneficial to keep the CO2 gas content under 5% as this minimize and chance of carbon pick up which was important with the low carbon stainless welds.

After i developed the argon mix, AGA introduced my mix to its US customers. AGA should have patented the MIX but the Swedes have a habit of ignoring what goes on outside Sweden. When I left AGA, I introduced my two part Argon - 2% CO2 gas mix with different North American companies such as Air Gas and Liquid Carbonic. Also I gave my argon 2% CO2 gas mix a name and called it STAINMIX, as this would eliminate the common MIG gas cylinder selection confusion that occurs with many weld shops that have cylinder storage racks filled with a wide range of MIG weld gases, (another indication of inexperienced weld shop management).

My 98% Argon - 2% CO2. Stainless, Duplex & other alloy steel MIG weld benefits:

SUMMARY OF ARGON - 2% CO2 STAINLESS GAS BENEFITS ON STAINLESS AND ALLOY STEEL GAUGE PARTS. In contrast to the higher energy and higher voltages required from a 90% helium - 7.5% Ar - 2.5% CO2 tri-mix, the much lower cost, and more gas in the cylinder, argon - 2% CO2 mix, will when short circuit or pulsed MIG welding thin gage (<2 mm) stainless parts;

[a] reduce weld burn through potential,

[b] reduce weld distortion potential,

[c] reduce weld oxidation potential,

[d] reduce the potential for weld cracks.

[e] reduced weld volt requirements, enables low parameter arc stability and parameters for more comfortable for the welder,

[f] reduce stainless weld fumes from lower weld voltage.

ALL ALLOY STEEL APPLICATIONS WILL BENEFIT FROM MY Argon - 2% CO2 mix. This mix is ideal for stainless steels short circuit welds with an 0.035 (1mm) wire on gage parts < 0.080, and it's a logical gas mix choice for all stainless welds with either an 0.035 - 0.045 wire in the Spray or Pulsed MIG modes. My gas mix has become a common global alloy steels MIG gas choice now for more than two decades, and as to be expected in this weld industry, I rarely receive a thank you note from anyone who either sells or uses the gas, (with the following exception below).

Note: You would typically not use my argon - 2% CO2 mix for carbon and high strength steel welds. Instead use my argon 15% CO2 mix. If more weld energy is required with either the short circuit, pulsed, or spray welds then the logical choice is the argon - 20% CO2 mix, which by the way is a European developed mix that through AGA in Cleveland, I introduced to North America in the 1980s.

E-mail: Hello Ed Craig.

I would like to thank you for the excellent information on your website, I'm a 4th year welding engineering student at Pen College of Technology and I'm currently knee deep in my internship. With the help of your information I was able to convince management to switch from the helium tri-mix to 98% argon - 2%CO2 mix for our 300 series stainless steel MIG welds. I'm also currently running tests to demonstrate to my head in the sand managements that running 100% CO2 is not the most economical situation for our structural steel welds (3/16 angle iron). I am also introducing your weld process control - best weld practice training programs to increase weld quality & efficiency both in engineering and fabrication.

Thanks again for all the information on your site

SO THE WISE WELD SHOP DECISION MAKERS THINK THEY SHOULD PROTECT

THEIR MIG WELDS FROM OXYGEN, BY HAVING OXYGEN IN THEIR MIG GAS MIX.

IF ANY WELD SHOP HAS BEEN USING TWO OR THREE PART MIXES THAT CONTAIN OXYGEN,

THIS IS ANOTHER INDICATION THAT THOSE MAKING THE WELD DECISIONS WERE IN THE WRONG BUISNESS.

THE USE OF ANY MIG GAS MIX WITH OXYGEN IS MORE THAN RIDICULOUS: Remember as we live on a planet with more than an abundant supply of oxygen and the industrial gas companies are always looking for a place to sell this product that they get and put in cylinders for next to nothing. Its especially ironic that when there are alternative reactive MIG gas choices, that the last product you want to put into a MIG weld gas mix is OXYGEN. But as P. T. Barnum and many confidence men used to say, "there's a sucker born every minute."

After I finished my Argon CO2 gas research on stainless "gage" parts, I then turned my research attention to MIG Spray Transfer on thicker stainless > 12 gauge applications. For decades most Spray and later Pulsed stainless MIG welds were often welded with two part Argon - 2% to 5% oxygen mixes, or with three MIG gas part mixes containing argon - CO2 - oxygen.

Please remember when pulsed MIG was being introduced when I was doing the MIG gas research in the nineteen eighties, that there was no pulsed MIG equipment that provided consistent pulsed drop transfer and could perform for two days in a row without doing something weird. With this in mind my MIG gas research was with MIG Spray, however my gas research results would also apply to pulsed MIG.Note: See the extensive evidence in my "Management & Engineers Guide to MIg" BOOK on why weld shops should be concerned with the use of pulsed MIG on common weld applications

Another useless mix. Argon - 2 to 5% Oxygen Mix.

Wow this Spray Transfer fillet on 304 Stainless is very oxidized, I wonder why?

ITS ALMOST 2020, AND I AM SORRY TO REPORT THAT AS ITS BEEN SINCE THE 1960s, THE GREAT GAS CON GAME CONTINUES IN THOSE GLOBAL WELD SHOPS THAT SUFFER FROM THE COMMON WELD SHOP DISEASE CALLED

"PROCESS IGNORANCEITIS."

ARGON - OXYGEN MIX: For almost 70 years, major global MIG Gas manufacturers, weld distributors, and also weld equipment / consumable manufactures have been recommending Argon - Oxygen mixes, first with Spray Transfer welds, and in the last 30 years with Pulsed MIG applications.

ARGON - OXYGEN MIX: Argon mixes with 2 to 5% oxygen have been a common global MIG gas mix sold for welding steels, stainless and alloy steels on SPRAY and PULSED MIG applications. From a weld perspective, this of course has always been an ironic gas mix as one prime function of a MIG gas mix was to protect the weld from oxide reactions with the abundant supply of oxygen in the atmosphere.

ARGON - OXYGEN MIX: In the 1960s when I was a teenager working in weld shops that utilized argon - oxygen mixes, or today in 2019 when I view the argon - oxygen gas mix recommendations, the bottom line from a MIG weld quality perspective, is that these mixes have always been a poor choice for any MIG welds as oxygen has a detrimental influence on the weld fusion and porosity.

Attaining optimum MIG weld fusion with all steels > 0.100 should always

be a concern, and a prime reason for the MIG gas selection.

Note any weld shop that is used to looking at weld macros should be aware that lack of fusion is a major concern and with most MIG welds on steels > 3/16. Even acceptable MIG weld fusion is rarely robust, and that's why its important for weld shops to be aware that the MIG gas selected plays an important role in the weld shop fusion attained.

Note: With steels, the higher the CO2 up to 20% the greater the weld fusion capability and the less porosity produced.

COMPARE MY ARGON 2% CO2 MIX WITH AN ARGON OXY MIX: Due to stainless MIG weld carbon pickup, CO2 gas content is limited for stainless welds at around 5%. In my weld gas research, for MIG welding stainless parts > 0.100 that should be using spray or pulsed, I examined the weld differences attained between my low oxidizing Argon - 2% CO2 mix, and the common Argon 2% to 5 % Oxy mixes.

Note: Both CO2 and Oxygen are reactive, however one percent oxygen is approx. 10 time more oxidizing than one percent CO2. In contrast to oxygen, the CO2 component in the argon MIG gas is unique. CO2 in the MIG arc causes dissociation of the CO2 gas into Carbon Monoxide and Oxygen molecules. To sustain that molecular dissociation requires more voltage than would be required if oxygen was used with argon. The CO2 MIG arc dissociation creates increased arc plasma energy, and the higher weld voltages create more energy. Low to moderate CO2 content also reduce weld oxidation potential. These CO2 attributes mean that in contrast to most mixes that contain oxygen, that the argon CO2 mix should enable superior weld fusion with less weld porosity potential, and irrespective what your gas sales rep states, this is something every MIG weld decision maker should want for their steels and alloy steel spray and pulsed MIG welds.

MY ARGON - 2% CO2, STAINLESS & WELD OXIDATION BENEFITS: In contrast to two or three part mixes that have oxygen, my multi-purpose Argon - 2% CO2 mix is not only beneficial on short circuit / pulsed stainless sheet metal parts < 0.100, but also benefits MIG Spray & Pulsed stainless welds of any thickness. The 2% CO2 will especially benefit MULTIPASS stainless MIG welds, as with these welds the weld heat buildup promotes greater oxidation potential and resulting weld surface oxides and slag islands can result in excess weld porosity or unacceptable weld inclusions.

Note: My argon - 2% CO2 mix is a logical choice for food industry MIG weld applications in which the weld surface cleanliness is always important. Keep in mind however, that with thin gauge MIG welds < 0.080, irrespective of the MIG gas mix utilized, oxidation will always be more sever as a result of the prolonged weld cooling times with the thin gauge parts welded, the increased cooling time enables the oxygen in the atmosphere to react with the slow cooling welds.

MY ARGON - 2% CO2 SPRAY & PULSED MIG STAINLESS FUSION BENEFITS: If your company is using Spray or Pulsed MIG on stainless parts that are > 3/16 (>5 mm), try the following. With a 1/4 (6mm) fillet weld, cut and cross section the fillet weld and do a macro examination of the fillet root which is usually quite narrow. The poor narrow root profile in that fillet adds to both hot weld crack formation in the root, and also to possible weld porosity entrapment in the rapid weld freeze, narrow root profile. Then do the same weld with my argon - 2% CO2 mix and again with a macro compare the fillet weld profile attained.

Ref: MILLER RMD MIG PROCESS & PIPE ROOT WELDS: The Miller weld application sales manager in the 2019 Tube and Pipe Journal article recommended for his companies modified RMD MIG process that when used for stainless pipe open root welds, that for the best weld performance with the Miller RMD, consider either a very high energy, 90 % He - 7.5% Ar - 2.5% CO2 mix, or use my very low energy Argon -2% CO2 mix. From my perspective this extreme weld energy statement on MIG welding roots, simply points out the the Weld Ignorance and Lack of MIG Weld Process Control - Best Weld Practice Expertise that comes from companies and management personnel that should simply know better. An open pipe root weld benefits from low weld energy and fast freeze weld characteristics, two things that a Helium TRI-MIX gas wont promote.

CO2 CONTENT INFLUENCE ON CARBON PICKUP & USING LOW CARBON STAINLESS ELECTRODES: I could also call this section, "what's good for the welding goose should be good for the welding gander." An important weld issue that for decades has neglected by the suppliers of electrodes and often the persons who produce weld codes specifications, is an issue which should have a great influence on the so called acceptance level of CO2 in a MIG gas when that MIG gas mix is used for welding the low (L) grade stainless applications, in which carbon is carefully regulated.

While engineers worry about the influence of with MIG welds from the carbon dioxide (CO2) gas content on the carbon content of the stainless welds, in contrast these same engineer will typically not be aware that if they had allowed the stick (SMAW) weld process to be utilized with Low Carbon Stainless Electrodes, the electrodes would typically provide a higher level of carbon content into the welds than will be attained with the equivalent MIG electrode low carbon stainless MIG wires.

SO ON STAINLESS JOBS IF A WELD SHOP USES LOW CARBON SMAW (STICK) ELECTRODES THEY WILL TYPICALLY BE PUTTING MORE CARBON INTO THEIR STAINLESS WELDS THAN THEY WOULD IF THEY USED LOW CARBON MIG WIRES.

ONE LOW CARBON LEVEL AMOUNT ALLOWED FOR SMAW, AND ANOTHER AMOUNT ALLOWED FOR MIG IS NOT LOGICAL. I read somewhere that it's difficult for the manufacturers of low carbon stainless stick electrodes to get the carbon to levels < 0.030%, which is the amount specified for the low carbon stainless MIG wires. So this electrode chemistry flexibility with two widely used weld process creates a double standard from stainless weld consumable manufacturers. And from an engineering perspective this fact should be considered unacceptable. However please note that my argon - 2% CO2 mix does not change the carbon content of a weld made with a low carbon MIG electrode.

From the 1980s to 1990s: Ed now Em developed or introduced to N. America, the following logical real world "TWO PART MIG gas mixes which are low cost and optimum for the majority of all MIG Steels, Stainless, Alloys and Aluminum applications. |

Most global industrial gas companies did not want the gas competitors to know what was in the cylinders they sold, and this often added more confusion to the already confused weld shop.

However when I was in a position to do gas mix development in the 1980s 1990s, there was never weld shop gas confusion in the weld shops that purchased my companies gas mixes. I ensured that anyone could look at a cylinder and on a large stick on label identify the cylinder as either a Steelmix, Stainmix or Alummix. And then to make it easy for the MIG welders I put my simplified MIG parameters required for any weld application on another label on the cylinders.

For decades MIG gas mix confusion benefitted who?

WEAK WELD MANAGERS, ENGINEERS AND SUPERVISORS WHO LACK THE ABILITY FOR PROCESS OWNERSHIP, AND ASK THEIR MIG WELDERS TO TEST A NEW MIG GAS MIX OR WELD WIRE WOULD BE LIKE ASKING A BLIND MAN TO DO A BRAIN OPERATION.

For those companies that employ weld decision makers that do not have the requirements for weld process ownership and believe that once the salesman has delivered his companies magic MIG gas mix, the welders should be given the task of testing that mix. I will simply say this. Ask ten welders including the weld supervisor, the weld parameter difference that will occur between an Argon - 20% CO2 mix and an Argon - 2% oxygen mix, and I guarantee you that you will get a glazed look from 20 eyes and receive 10 very different answers. This confusion is called lack of weld process control expertise, and you know I have a solution for your weld shop on this important topic.

Of course all weld decision makers who consider worthy of the wages paid to them should understand MIG weld process controls - best weld practice requirements and especially the influence of the MIG gas mix selected. Its likely a waste of time but why not try this MIG Weld Gas Test: If you would like to learn my manual and robot MIG and flux cored weld process controls - best weld practice, self teaching - training resources click here.

Carbon Steels and MIG Gas Selection Made Simple:

With CV MIG equipment that can provide sufficient weld current, Spray Transfer occurs on steels, stainless and other alloy steel applications with specific argon mixes. The transition point from short circuit or globular requires a minimum, weld amp / volt requirement.

The welder achieves spray when a weld stream and weld droplets smaller than the wire diameter cascade across an open arc from the wire tip to the weld. Depending on the spray transfer weld parameters used, the weld transfer can at the spray transition point provide single drops and with the weld hood down this would look similar to pulsed. At higher amps the spary weld produces a combination of smaller weld drops and a stream of molten metal.

MIG Pulsed transfer enables an open arc transfer of weld drops from rapid high peak to low arc sustaining back ground current changes. With some of the pulsed MIG equipment available in 2019 as with the OTC, you will an improved stable low amp pulsed MIG range that enables the successful use of pulsed on thin gauge steels. Pulsed will use straight argon for aluminum, and argon mixes for steels and alloy steels. When i select a gas mix for a steel pulsed MIG weld I use the same weld logic that applies to selecting a spray mix. Do I want high weld energy and what about the gas mix reactivity? My gas mix recommendations enable the best possible weld energy with the lowest reactivity.

So is this transfer Pulsed MIG or Spray?

With my argon - 15% CO2 mix, this is spray at its transition point.

MIG Spray transfer Gas Myths that have been created by the North American so called MIG weld experts.

If you had been around weld shops in the 1980s - 1990s perhaps you read an erroneous MIG gas statement somewhere that states, "you cannot get Spray transfer with an argon CO2 mix that contains either - 10 - 15 - 20 or 25 % CO2.

REMEMBER THESE ARE THE COMPANIES THAT THE WELD SHOPS WOULD TURN TO FOR MIG ADVICE: 1990: MIG Weld Reality GAS Fact. For thirty plus years, major companies that should have known better such as Lincoln, Miller, BOC, Hobart, Liquid Air, Air Products, Liquid Carbonic and almost everyone else in North America and Europe who made MIG welding equipment, consumables and weld gases, all stated in either their weld books or promotional MIG products literature, "that you could not get MIG spray transfer on carbon steel welds using either one of the above argon - CO2 mixes with any MIG electrode diameter.

The so called welding experts providing MIG process advice at the worlds largest weld equipment and consumable companies must have never worn a welding shield when evaluating gas influence on the MIG spray transfer mode. The weld reality was if you knew what you were doing, with the common MIG wire diameters utilized, that spatter free spray transfer welds was attainable with argon - 25% CO2, however if you lowered the CO2 to around 20% spray was possible with all MIG wire diameters, and as you lowered the CO2 content, the voltage and weld energy requirements were reduced.

2019. PLEASE NOTE, THIS IS THE ONLY PLACE IN THE WORLD WHERE YOU WILL LEARN THE FOLLOWING MIG GAS INFORMATION, AND I FIRST WROTE THIS ALMOST 30 YEARS AGO.

I don't recommend argon - 25% CO2 as it limits traditional CV Spray transfer with the common MIG wire diameters utilized. However for those so called weld experts that talked about how 10 or 20% CO2 content would not enable spatter free spray, these characters would definitely doubt that an argon mix containing 25% CO2 could attain spray transfer. My reply to this is put on a weld shield and do the following, after all seeing is believing.

For my argon - 25% CO2 MIG Spray test. The object is produce a 1/4, 6 mm fillet weld on >3/8 (>9mm) plate. Grind the area to be welded on the plate so the mill scale is removed. Using a CV 350 amp power source or larger, (don't use an inverter). Set an 0.045 (1.2mm) MIG wire feed rate at 450 in./min (11.4m/min), don't have a digital wire feed control? set the wire feed knob around the 2 o'clock position. Important, to attain SPRAY with 25% CO2, you will use a higher than normal spray weld voltage, typically 32 to 36 volts is required, (ensure the CV MIG power source used has this capability). The high weld voltages required for the spray mode with the 25% CO2 will produce defined spray transfer in which the weld droplets and stream transfer are smaller than the wire diameter.

However there are negative attribute of using argon - 25% CO2 and 0.045 wires. The high amount of CO2 (high voltages) provide high and often excess spray energy. The resulting high arc heat and weld heat can be uncomfortable for welders. Also with 25% CO2, the high weld fluidity that results may cause issues such as undercut, oxidization or poor weld puddle control on specific welds. However the major issue with 25% CO2 is when using the common 0.035 (1 mm) MIG wires, then you will find that consistent CV MIG spray is simply not attainable. In contrast Spray transfer is however attainable with all MIG wire diameters including 0.035 when using argon mixes with 20% or less CO2.

Note: MIG Gas Fact: Any global weld shop that used or is using the 75% Ar - 25% CO2 mix has been simply restricting the MIG process weld performance potential, therefore this gas choice simply revealed a weld shop without effective weld management and supervision.

Reducing the CO2 gas content in an argon mix to a maximum of 20% for carbon steel welds, brings the spray transition current down and also brings the required spray weld voltages down to comfortable weld levels in which the welder can typically use 25 to 32 weld volts for spray transfer with the common 0.035 - 0.045 (1 - 1.2 mm) wires.

Carbon and Alloy Steels and MIG Tri-Mix Gas Mix Weld Facts.

The minute you see any "three part gas mix" being used for the common carbon steels and alloy steels,

you know you are in a weld shop that knows little about MIG welding, and their gas suppliers love them.

TRI MIX FOR CARBON STEELS SHOW THE GAS MAKETING PERSONNEL HAVE DONE A GOOD JOB: For the last two decades, one the most widely marketed gas mixes promoted in North America for MIG welding carbon steels has been a tri-mix typically containing Argon with 5% to 10% CO2 and 1% to 2% OXY.

TRI-MIX..... ARGON - CO2 - OXY.

3 Part Gas Mixes for "Carbon steels" and MIG Weld Reality.

Up to the end of the nineteen eighties, the industrial gas

(CON)marketing folks and their weld sales personnel focus was on converting straight CO2 users to argon mixes such as argon 25% CO2 and argon with 2 to 5% Oxy. With the intense competition for the highly profitable industrial gas products in global weld shops, the confused two part mixes quickly turned to three part mixes, and eventually there are sure to be four part mixes available for MIG welding steels and alloy steels.

REPEAT. WHY NOT TRY MIG WELD PROCESS CONTROL EXPERTISE INSTEAD OF GOING ALONG WITH GAS SALES BS: In contrast to the lower cost, two part argon 2 to 20% CO2 mixes, the three part Argon - CO2 - Oxy mixes used for carbon steel and the common alloy steel welds, offers no practical weld benefits that can be measured in terms of weld quality, weld metallurgy or weld productivity. However the three part mixes can create negative attributes for the weld. For those weld shops it would be much much cost effective for a weld shop to read the info at this site, utilize a lower cost two part gas mix, and then ensure the welders are provided with my low cost MIG weld process control training program.

Note: There are some "alloy steel" MIG welds in which slight weld benefits are attained from adding a third component into the gas mix, see my recommendations below.

E Mail Question to Ed. Ref METAL CORED WIRES AND ARGON OXY.

From Kevin M Gough...

Ed, as you know I ordered your MIG and flux cored process control materials and book. I love the straight forwardness of the weldreality site and your attention to two important details for the weld industry, truth and credibility!. I have read through most of the posts on your QA forum, and I have yet to see any refute from a any gas or equipment supplier. Not that I am naive enough to believe they would respond, the bottom line is they simply can't!

My question is, are they at it again? Here is the latest gas to get thrown at me- Hobart and BOC are currently promoting argon 95% - oxygen 5%, for use with metal cored wires. The sales men went on about such selling features - as lower voltage possible increase of travel speed, equal heat input with no loss of penetration- no spatter, no undercut or visible porosity on "mill supplied" or medium rusted plate. Especially effective on welding 16 gage galvanized material in any position.

I tried the argon oxy gas mix and metal cored wires and did some weld destructive testing on my own. On a a rust filmed piece of 3/8 low carbon steel, type 50W, I made a tee joint- and welded it at the settings they used, 25V and 265 ipm wire speed. This produced approximately 325 amps which is what they set the machine at. You get no undercut regardless how hard you try to change the gun angle- very little spatter and very little silicon deposit on the face of the weld. However and here is where things got interesting I broke the specimen- and found excess root porosity or pockets of "voids". To correct the weld problem we changed the weld travel speed to slower than we typically use. Also increasing the wire feed speed to render 350 amps or above which puts us back where we started from or further. All the best. Sincerely. KMG

.

Ed's Answer.

Forget about the metal cored wires this is simply an unnecessary weld consumable expense. MIG or metal cored wires, the argon - 5% oxygen gas mix like the argon - < 20% CO2 mixes, promote spray transfer with solid or metal cored wires, however with the oxy mixes especially with 5% Oxy. enables lower spray transition weld current. Argon oxy mixes typically result in a weld penetration profile with narrow finger or nipple at the root. That narrow finger weld root solidifies rapidly and the highly oxidizing oxygen mixes can promote gas pores that get trapped in that narrow fast freeze weld area.

The narrow finger fusion weld profile freezes rapidly trapping the oxygen gas oxide reactions, increasing the weld porosity potential. Remember a primary purpose of a gas mix is assist in the weld energy attained through the weld voltages for optimum weld fusion and also to prevent oxygen and nitrogen from entering the welds.

So lets see, with the oxy mix and metal cored combo, you have two consumables that reduce the weld energy potential and produce welds with a narrow fast freeze root finger profile. The argon oxygen mix brings to the weld a gas mix with too much oxidization potential. Instead consider lower cost MIG wires with my lower cost argon CO2 mixes. With the higher energy argon 15 - 20% CO2 mixes, and optimum MIG parameters and techniques, as provided in my process control training programs, superior weld fusion and less porosity will be attained. As to reducing undercut potential, set voltages with minimum arc length (constant crackle) with minimal weld spatter. And to also reduce undercut and and low weld surface slag islands, you get that with any of my recommended steel argon CO2 gas mixes for carbon steel welds using a E70S-3 MIG wire, (always first choice) instead of the common E70S-6 wires.

Around 1999,

at this web site, I placed the following challenge to the major Gas Companies

Gas Companies, Put Up or Shut Up.

A challenge to any major industrial gas manufacturing company.

In contrast to a two part argon 2 to 20% CO2 mix of my selection, I believe that no gas company can show any real evidence of practical, measurable, welding quality, weld metallurgical or weld productivity benefits from any three part "Argon - CO2 - Oxy" or any He - Ar - CO2 gas mix when welding steels. If a gas company could prove it's point, I will pay $5000 to any charity of it's choice.

Its 2019 and of course the industrial gas companies have never responded to the challenge, after all why would they want to show their product deceit, ignorance and sales tactics dirty laundry to their weld shop customers that in reality should know better.

WHO WRITES THOSE GAS BS ARTICLES THAT ARE IN YOUR WELD MAGAZINES? Have you noticed since the introduction of three part MIG gas mixes for common steels, the lack of technical articles on MIG gas mixes. Have you also noted that when some one does write an article on the cloudy, confused MIG weld gas subject, that the author typically represent the gas company that's trying to promote a new three part magical gas product.

INCREASE WELD OXIDATION POTENTIAL & LOWER WELD ENERGY POTENTIAL, ARE THEY INSANE? If the weld shop stops using an Argon - 10 to 20% CO2 mix, and then uses a three part Ar - CO2 - Oxy mix, they are simply increasing their weld oxidation potential, (more porosity), changing the plasma profile to one less suited to optimum weld fusion profiles, and with lower plasma density produced, providing lower the weld energy potential, (inferior fusion).

Its easy to see with a weld macro, the three part mix the influence on the weld fusion attained. When welding fillet welds and that oxygen influence on the plasm typically creates a narrow finger penetration profile with spray and pulsed welds.

The area of the narrow finger fusion freezes rapidly and this can trap the oxygen influenced oxide reactions, increasing the weld porosity potential. Remember a primary purpose of a gas mix is to attain the best possible weld fusion and prevent oxygen and nitrogen from entering the welds.

BACK IN THE 1960s EVEN THE ENGLISH WELD INSTITUTE GAS RESEARCHES WERE AWARE THAT 3 PART MIX FOR CARBON STEEL MIG WELDS WERE SIMPLY BS. Apart from the 40 years that I have evaluated MIG gas mixes, perhaps you would like another unbiased point of view on three part mixes for carbon steels. Back in the nineteen sixties when I was a young kid breathing the fumes and MIG welding tractors at Massey Ferguson in England, the British Welding Institute, (at that time an unbiased weld research organization), carried out MIG gas research. Their MIG gas research indicated that in contrast to argon mixes with 5% to 20% CO2, three component gas mixes containing argon - CO2 & OXYGEN when used for welding carbon steels "provided no practical weld benefits".

MIG WELD GAS COST FACTS:FOR DECADES, ONE OF THE POPULAR MIG GAS MIXES IN NORTH AMERICA FOR MIG WELDING CARBON STEELS, HAS BEEN A THREE PART MIG GAS MIX CONTAINING ARGON WITH 5 to 10% CO2 PLUS 1 to 2% OXY.

[1] GAS COST FACT: A THREE PART GAS MIX TYPICALLY COSTS 20 TO 50% MORE THAN A TWO COMPONENT ARGON - CO2 MIX THAT CAN GET SUPERIOR MIG WELD RESULTS.

[2] GAS COST FACT: THE THREE PART MIG GAS MIXES WILL HAVE LESS GAS IN THE CYLINDER THAN A TWO PART ARGON CO2 MIX. IN CONTRAST, THE ARGON - CO2 CYLINDERS WILL KEEP THE WELDER RUNNING FOR AN APPROX. ADDITIONAL ONE HOUR MIG ARC TIME.

[3] GAS COST FACT: THE THREE PART MIXES WITH OXY ARE MORE OXIDIZING THAN MANY ARGON CO2 MIXES INCREASING THE WELD POROSITY POTENTIAL, DECREASING SIDE WALL WELD FUSION CAPABILITY AND PROVIDING LOWER IMPACT PROPERTIES. SO YOUR WELD REPAIR COSTS WILL BE HIGHER AND STOCK UP ON THOSE GRINDING WHEELS.

[4] GAS COST FACT: WELD FUSION IS NOT AN ISSUE UNTIL NDT OR DESTRUVTIVE WELD TESTS ARE CARRIED OUT. THE THREE PART GAS MIXES WITH OXY TYPICALLY PRODUCE INFERIOR WELD FUSION, (FINGER) PENETRATION. FINGER PENETRATION LEADS TO A NARROW ROOT BAND IN WHICH THE WELD ROOT FREEZES SO RAPIDLY THAT GAS PORES MAY NOT HAVE TIME TO ESCAPE. THIS NARROW ROOT AREA IS A GOOD LOCATION FOR LACK OF FUSION, WELD CRACKS LARGE PORE POROSITY.

[5] GAS COST FACT: THE THREE PART MIX WITH OXY IS MORE SENSITIVE TO WIRE STICK OUT CHANGES, AND IS MORE SENSITIVE TO MILL SCALE, COATINGS OR SURFACE CONTAMINATES. THE THREE PART MIX ALSO REQUIRES LOWER WELD VOLTAGES, (THANKS TO THE OXY). THESE MIXES WILL HAVE LESS ARC STABILITY THATS MAY BE NOTEABLE WITH AUTOROBOT / AUTOMATED HIGH DEPOSITION / HIGH WELD SPEED APPLICATIONS.

If you still believe a three or four part MIG gas mix is necessary for your weld applications, give me a call, I am looking for investors to buy my boat building business located next to the Wizard of Oz house here in the middle of Kansas. If you need more convincing, you could read my 600 page "Management / Engineers Guide To MIG BOOK,

This is one of my many process controls - best practice resources that can educate weld decision makers.

However sad to say few sold, as most weld decision makers would rather get weld advice from a weld sales rep.

My 600 page book on MIG and my MIG process control training resources

has all the info you need, I am sorry there is no BS included, you know where to get that.

Its 2019 and after 50 years in this frustrating business that I still love, my message on gas mixes has never faltered. If the world's supply of oxygen was lost to the weld industry tomorrow, as it would have for the last 70 years, it would have zero impact on the global MIG welding industry. How ever it would have an impact on the profits attained by industrial gas suppliers and there distributors.

FOR DECADES THIS HAS BEEN ED'S (EM'S) MIG GAS SELECTION.

SIX BEST MIG MIXES FOR THE MAJORITY OF GLOBAL MIG WELD APPLICATIONS.

Ed now thankfully Em, both developed and introduced this Gas Mix to North America in the 1980s.

Argon - 15% CO2:

Compatible CO2 mix range allowance would be argon with 13% to 17% CO2.

THIS IS A MULTI-PURPOSE MIG MIX THAT I DEVELOPED AT AGA IN CLEVELAND IS IDEAL FOR BOTH MIG & ALL POSITION GAS SHIELDED FLUX CORED (EX0T-1) WELDS.

Weld applications for my Argon - 15% CO2 mix:

With the MIG process this mix is ideally suited for carbon and high strength steels welded with Short Circuit, Spray and Pulsed transfer.

With the Gas Shielded Flux Cored welds. Use this mix with all position wires for carbon steels, low alloy steels, stainless, Inconel and duplex. You don't want to use less than 15% CO2 for the all position gas shielded flux cored wires and note that argon 20% CO2 will supply slightly more weld energy than this mix. If mill scale is a problem or weld fusion needs to be increased evaluate the all positions wires that are developed to be used with straight C02 from Kobelco.

[] An argon - 15% CO2 mix is without question a good "high energy, MULTI-purpose gas mix" suited for most weld job shops.

[] The argon 15% CO2 mix provides more weld energy than the common argon - 8 to 10% CO2 mixes, and this is beneficial when MIG spray or pulsed transfer is used on carbon steels or high strength steels that have mill scale, primers, surface contaminates and galvanealed, galvanized coatings.

[] In contrast to argon - 25% CO2 which cannot provide optimum spray with an 0.035 wire, the argon - 15% CO2 gas mix provides stable spray or optimum pulsed welds with all steel and low alloy steel wire sizes.

[] With short circuit or pulsed MIG on carbon steel gage applications < 2 mm, my argon - 15% CO2 mix will be superior to both argon - 25% and argon - 20% CO2, as the 15% CO2 can reduce the weld burn - through potential.

[] The argon 15% CO2 gas mix provides optimum weld results when used with all position welds using gas shielded flux cored electrodes welding carbon steels, low alloy steels, stainless, duplex and Inconel.

[] The argon 15% CO2 mix is also beneficial for robot or mechanized "high speed" welds on carbon steels > 1/8 > 4mm. In contrast to three part mixes containing argon - CO2 - oxygen, argon oxygen mixes, or argon with 8 to 10 % CO2 mixes, the higher voltages required for this mix and the higher dissociation (HIGH ENERGY) properties of CO2 assist in stabilizing the arc and can provide superior weld penetration.Note: The argon 15% CO2 with "all position", carbon steel gas shielded flux cored welds, but also for alloy steels such as stainless and inconel flux cored welds.

Note on Argon - 20% CO2 mix: This mix was a common mix sold in Europe for decades before I introduced it with AGA Cleveland to the USA in the nineteen eighties. Today argon 20% CO2 is a common mix sold in North America. However be aware that it's not uncommon with many gas distributors to provide the 20% CO2 mix with a wide CO2 range allowance. Many weld shops were not aware that when they asked for a cylinder with argon - 20% CO2, they they might end up with cylinders that had > 23% CO2. With this amount of CO2, optimum MIG spray transfer with the carbon steel 0.035 MIG wires would not be possible. My Argon - 15% CO2 mix allows for less opportunity for the MIG gas supplied in cylinders to be over the 23% max CO2 content.

ARGON - 10% CO2.

PULSED & Spray MIG Welds and all carbon steels and low alloy steels, also used for short circuit or pulsed on carbon steels and alloy steels < 0.080.

Compatible CO2 gas mix range, 8 to 12% CO2.Applications:

[] Best low weld energy MIG gas mix for Spray and or "Pulsed" carbon steel and low alloy steels welds on < 1/4 (< 7 mm) components. On many robot or manual carbon steel welded parts, the weld heat from high wire feed spray or pulsed welds can cause, distortion, weld burn through or excess weld fluidity causing weld undercut or oxidation. The fact that this gas provides lower energy than higher content 15 or 20% CO2 mixes makes it beneficial for these applications.

[] What is really interesting about this medium energy gas mix is that its also the best choice for welding thick steels as long as the mill scale and other surface contaminates are removed. When spray or pulsed transfer welding horizontal fillets larger than 1/4 (> 6 mm) or especially welding MULTI-pass fillet or groove welds in which the "weld heat buildup is notable", the welder is aware of the high weld fluidity being attained. That weld fluidity increases as the CO2 content of the gas increases. Argon with 15 or 20% CO2 may produce multi-pass welds with more fluidity and oxidation than the argon - 10% CO2. So on the thick carbon steels, if you want improved multipass weld control consider argon - 10% Co2.

Note: With this same weld logic, if you are using the 10% CO2 mix with the pulsed / spray process on steels > 6 mm thick and you need more weld fusion, you should change the gas mix to a higher CO2 mix such as 15% to 20% CO2 mix.

Another mix that Ed developed and introduced to North America.

98% Argon - 2% CO2.

Stainless - Duplex and alloy steels.

CO2 composition range. 1.5 - 2.5% CO2.

Its an ironic point that for decades I have been criticizing the industrial gas companies and distributors and now they are selling and profiting from my MIG mixes with out so much as a thank you. I developed this unique argon - 2% CO2 mix for stainless and alloy steels that benefit from low weld oxidation. I did the gas research to develop this mix while at AGA in the nineteen eighties.

The argon - 2% CO2 mix is very low oxidizing mix is suited to MIG Short Circuit, Spray and Pulsed welds on all stainless / duplex and high alloy weld and clad applications. I would also recommend this mix for anyone MIG welding very thin carbon steels and low alloy steels on gauge welds on parts that are thinner than < 0.040.

Note: Do not use this mix with any flux cored wires or with GTAW applications.

So remember when MIG welding stainless gauge short circuit applications, forget the common, ridiculous, more costly 90% Helium - 7.5% Argon - 2.5% CO2 Tri mix. This is a premium priced gas mix that the major gas suppliers love to sell, and also remember that when the gauge parts are > 0.080 switch the weld transfer to low spray with 0.035 wire or pulsed with 0.045 wires.

COMPARE WITH HELIUM TRI- MIX.. In contrast to the more costly, higher energy, helium tri-mix, the argon - 2% CO2 mix when used on thin gage applications can provide;

[1] less part distortion,

[2] less weld burn through potential,

[3] less contact tip issues,

[4] improved arc stability,

[5] lower cost gas,

[6] more gas in the cylinders,

[7] less opportunity for stress corrosion cracks, hot crack, and micro cracks.

COMPARE THE TRI MIX WITH AN ARGON - OXYGEN MIX? In contrast to the argon oxygen MIG mix recommended by all the gas companies for stainless spray and pulsed applications, my argon 2% CO2 mix can result in less oxidized, cleaner MIG spray or pulsed welds with less weld porosity potential.

Note: When used for "low carbon" stainless applications, the carbon content in the weld will be acceptable with this low CO2 gas mix for all short circuit, pulsed and spray stainless applications.

So yes. I did develop a Tri mix as a little nitrogen might help my argon CO2 mix

My Argon - 2% CO2 - 1% Nitrogen mix for MIG spay and pulsed Duplex Steels.

Mixing range for the Nitrogen. 0.75 to 1.75%

Mixing range for the CO2. 1.5 - 2.5%.

I developed this special tri-mix in the early nineteen nineties. On most duplex MIG applications, my stainless gas, argon - 2% CO2 mix is sufficient, and I added the nitrogen to my argon CO2 mix for the following reasons.

Note: I have never proven the weld results for the addition of the nitrogen into this gas mix. And if i was welding duplex there is only one weld process I would select and its a process called TIP TIG that simply requires argon. This is a process that I introduced North America and Australia to around 2008 - 2009.

DUPLEX MIG WELDS AND NITROGEN CONTENT: The theory is when a small amount of nitrogen is added to the MIG welds, this can be a potent austenite stabilizer. The addition of nitrogen to the duplex weld / steel will promote structural hardening by a solid solution mechanism. The small nitrogen addition therefore can raise both the yield strength and ultimate strengths of the duplex without impairing toughness. The low CO2, combined with the benefits of low nitrogen content may offer benefits for duplex MIG welds.

My tri-mix will also provide stable short circuit, pulsed and spray transfer. If you are using short circuit, STT or RMD for duple pipe roots, (you should be using TIP TIG) first try my argon - 2 CO2 mix. If the Duplex root or fill pass weld mechanical properties are not what you desire then try this MIG gas mix.

If more weld energy / fluidity is need for pulsed MIG or spray transfer pipe fill passes on those duplex applications, try my following tri-mix recommended for either Duplex or Nickel applications

Note: Using the flux cored wires for duplex or inconel use my argon 15 - 25 % CO2 mixes.

Note on how well mixed the gas mixes are: It's beneficial with cylinders that contain very small amounts of a gas additions, if those cylinders contain DIP tubes that send the gases to the bottom of the cylinders which assists in the gas mixing. Order my TRI-mixes gas mix through a "specially gas supplier" and ask for a certificate of composition compliance.

Another TRI MIG mix developed and introduced be Ed

59% Argon - 40%Helium - 1% CO2 for Nickel Alloys:

Mix range. CO2. 0.75 to max 1.5%.

Reduce Oxidation on sensitive Nickel welds.

Note: The low CO2 content must be carefully mixed and controlled. Order cylinders with dip tubes. Pay a little more and order this gas mix from specially gas facility to ensure the mix is correct.