|

|

Welcome to information on Pulsed MIG Clad Welds.

The https://weldreality.com site was first established in 1997 by Ed Craig. Contact Ed. ecraig@weldreality.com

PULSED MIG AND CLAD WELD INFORMATION AND BEST PRACTICES.

When employees lack MIG and Pulsed MIG weld process control - best weld practice expertise, the weld shops are simply throwing money out of the window, and as viewed in the power station, water wall clad application (below), this company is dramatically adding to the clad welding and costly consuambles costs and also are not likely aware that they are shortening the life of the water wall boilers.

Clad weld consumables can cost from $7 to $30 a pound, so yes while weld dilution is an important consideration of a clad weld, also clad weld consumable waste should also be givene consideration.

POOR Cladd Repairs on Power Station Boiler Water Walls.

Poor pulsed MIG cladd weld procedure used. Poor pulsed MIG power source selected. Poor weld practices used.

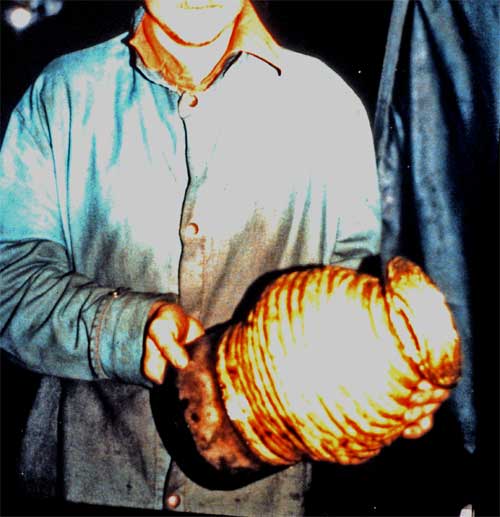

Above: This water wall Pulsed MIG clad application photo was proudly displayed in a weld magazine: The magazine article on boiler wall clad welding was about a new pulsed MIG power source available from Miller Electric, and the suitability of this pulsed unit to clad weld this water wall application with inconel.

The clad welds in the photo reveal poor pulsed MIG transfer weld characteristics, results (too sluggish) that reveals a poor pulsed MIG program for the alloys used. Also poor weld practices and techniques.

The clad welds shown above are providing inconsistent, unnecessary weld overlap, poor and excess weld at the clad

tie-ins, and sluggish welds that would with NDT reveal inconsistent fusion and clad dilution. Also the excess weld start stops did not help.

A clad weld operation such as this can dramatically negatively effect the boiler wall life by producing excess distortion, uneven wear, unnecessary stresses stress risers, weld issues that can reduce the boiler operation efficiency and longevity.

In contrast to above Ed's untouched, single pass MIG Clad Welds on Water Wall tubes.

Pulsed MIG Vertical Down. Inconel 622 on Boiler Water Wall taken from a 3000 sq/ft clad section, Note weld fluidity, uniformity and consistency with the welds, and especially the tie-ins weld overlaps.

As Weld Manger Ed's - Em's contribution to the Global Power and Waste Management Industries.

Welding Services (WSI) Atlanta, changed to Aquilex: WSI is primarily involved in repairs and refurbishment in the power, waste energy and nuclear industries. In terms of water wall clad welding, WSI has clad approx. 80% of the North American boilers. Each year, WSI uses approx. one million pounds of Inconel 625-622 and 300 series stainless weld wire for cladding boiler water wall tubes.

Around 2006, I WAS REQUESTED TO DEVELOP A NEW WATER WALL CLAD PATENT FOR WSI:

While WSI produced some of the most innovative, automatic MIG cladding equipment available around the globe, WSI did not have a resident pulsed MIG expert who had the weld process controls - best weld practice expertise that was necessary to make radical improvements to it's water wall clad MIG welds.

I was employed by by WSI to be the companies weld manager, and in less than 6 months, as the following pictures indicate, I dramatically improved the single pass water wall overlay weld quality and a new USA and European clad weld patent was developed.

THE MOST DESIRABLE CLAD WELD ATTRIBUTE IS CONSISTENTLY ACHIEVE THE LEAST POSSIBLE PULSED MIG WELD LESS DILUTION:

CLADDING AND IMPROVING THE WATER WALL BOILER LIFE & OPERATING EFFICIENCY:

As many in the power industry are aware, with any water wall clad weld application "less is always better". With less clad weld shrinkage and less clad weld defects, the boiler water walls will operate more efficiently when the single pass clad weld surface is as thin as possible and when the clad weld pass thickness is both uniform and free of weld defects.

The traditional automated pulsed MIG clad welds on boilers would produce clad welds similar to the macro pulsed MIG clad weld picture on the left. In most cases, too much MIG weld filler would be applied, too much weld dilution or too many weld layers. Also when automated MIG clad welds were provided which should have the best weld controls, due to inadequate weld automation and poor welds, the automated welds would also typically, lack consistency, uniformity, have poor weld tie-ins and produce welds with extensive lack of fusion, and welds that create unnecessry weld heat influence on the water wall tubes.Inconel clad filler metals typically can cost $20 - $30 a pound. With these costly MIG weld wires, it makes no sense to produce excess welds and create unnecessary weld heat and excess stresses and deformation on the boiler walls. In contrast, my new clad patent dramatically improved thesingle pass clad weld quality, and dramatically reduced the typical single pass clad weld thickness. These single pass welds also provided superior chemistry. and the bottom line also provided extensive clad cost savings from the reduced weld wire and rework requirements:

DRAMATIC REDUCTIONS IN CONSUMABLE WELD COSTS PER-OPERATION.

With Inconel clad wires at $20 - $30 a pound and large water wall / vessel tank or pipe areas to be clad, the clad weld consumable costs can typically be a large part of the cost of a clad application costs. My new pulsed MIG procedures - practices reduced the amount of clad single pass, clad weld overlay by approx. 28%.

WITH SINGLE PASS CLAD WELDS, YOU HAVE UNIQUE WELD REQUIREMENTS FOR THE CLAD WELD SURFACE TIE-INS AND FOR THE CLAD TO TUBE WHICH REQUIRES MINIMUM CLAD WELD DILUTION:

With water wall clad applications, the minimum, "single pass" Inconel weld clad chemistry required is 20% chrome. As the filler metal typically provides approx 21% chrome To attain the minimum chrome requirements, the pulsed MIG weld procedures with the vertical down clad welds consistently attained minimum weld dilution < 8%, while achieving consistent weld fusion on the carbon steel boiler tubes.

BOILER SHUT DOWN IS COSTLY AND WELD TIME IS VERY IMPORTANT WHEN CLADDING LARGE WATER WALL AREAS THAT SOMETIMES REQUIRE OVER 1000 sq/ft OF CLADDING. TO SPEED UP THE OPERATION, THE CLAD PROCESS NEEDS TO PRODUCE THE HIGHEST POSSIBLE WELD DEPOSITION RATES:

The primary part of clad weld costs on large weld areas as found with most clad boiler wall applications, is dictated by the MIG weld deposition rates attained. My patented clad procedure with the unique, WSI automated weld equipment, enabled a single operator controlling two guns to deposit approx. 30 lbs/hr.

Excess weld spatter with any MIG weld mode is an indication of

LACK OF MIG WELD PROCESS CONTROL EXPERTISE.

2006: My patented pulsed MIG weld operation on the left. This gun was providing 15 - 16 lb/hr with the lowest possible single pass pass weld dilution. Note the absense of weld spatter at a time period (10 years ago) when the pulsed MIG technology was and still is in many instances a joke..Compare with the so called normal water wall pulsed MIG clad welds on the right:

Unless you sell the costly stainless or Nickel clad weld consumables, with clad boiler welds, OF COURSE LESS IS BEST.

Above left my 2006 "single pass" clad welds provided clad weld dilution so low that the

stainless chrome content was always above 20%.

Before I got involved with boiler water wall welds, the picture below was considered by WSI to be an optimum, Inconel 622, Vertical Down, automated Pulsed MIG, water wall, clad application.

Below, My untouched, single pass patented stainless / inconel weld showing obvious MIG clad weld quality

Note my smooth single layer MIG clad surface with optimum weld blend ties ins. This clad application was delivered from a low cost, $5000 pulsed MIG power source in 2006. This pulsed MIG clad weld has a smooth finish similar to a $250.000 laser - powder clad overlay. In contrast to the conventional water wall clad MIG welds, and in contrast to what WSI had been producing for decades, Ed's pulsed MIG process change required 28 % less weld metal per sq/ft of coverage. These single pass, low dilution welds also provided > 20 % chrome.

I developed the best posssible MIG gas mix for stainless and inconel alloys.

UNIQUE PULSED MIG CLAD GAS MIX DEVELOPED BY ED - EM.

The vertical down 622 Inconel / stainless clad MIG welds in Ed's patent were derived from a low cost, five thousand dollar, pulsed MIG power source and a unique Inconel MIG gas mix that was also developed by Ed. (See the MIG gas data section at this site).Note: This patent would not have been possible without the Aquliex, (WSI), customized. automated MIG weld equipment that compensated for the wire stick out and arc length variations that resulted from the water wall curves.

MY PULSED MIG CLAD PROCEDURE BECAME A PATENT FOR THE COMPANY THAT PROVIDES MORE CLADD WELD THAN ANY OTHER GLOBAL CLAD COMPANY.

After a few months of pulsed MIG clad weld process development, my final Inconel 622, single pass, clad weld results were developed for WSI, (Aquilex) Atlanta.

In 2010 an International - USA patent on cladding was presented to Ed and WSI.

ELECTRO SLAG WELDS, WHY BOTHER?

ON LARGE SCALE POWER PLANT WELD APPLICATIONS, I DID A COST - QUALITY ANALYSIS OF ELECTRO SLAG WELDS (ESW) versus MIG FOR THE WORLD'S LARGEST CLADIING COMPANY.

WITH THE MIG PROCESS CONTROLS - BEST PRACTICES THAT I PROVIDED. I PRODUCED SUPERIOR MIG CLAD QUALITY AT LOWER COSTS THAN THE ESW SYSTEMS COULD PROVIDE.

THE MIG CLAD DILUTION IN MY 30 POUND / HR - PER HR. TWIN TORCH OPERATION RESULTED IN SINGLE PASS CLAD MIG WELDS WITH < 5% Fe AND > 20% CHROME.

COSTLY MIG EQUIPMENT WAS NOT NECESSARY:

BY THE WAY IT'S NOT NECESSARY TO PURCHASE A HIGH COST FRONIUS OR ANY OTHER HIGH COST ELECTRONIC MIG UNIT TO ACHIEVE THE CLAD RESULTS.

With the USA / European MIG patent that I generated for single pass clad welds used on boiler water walls, tanks, vessels, pipe or valves, I used a pulsed MIG MIG power source that cost approx. $6000.

Note: See ESW versus MIG below.

2015: Note: You are wasting money if you spend more than $7000 on a power source for any MIG clad application.

The the best process for clad welding when the highest weld quality is required is not a Hot or Cold Wire TIG process, it's the far superior TIP TIG process. This is a process that I introduced to North America and Australia. Visit the TIP TIG section at this site.

Follow up eight years later in 2014:

From Ankit Jindal, Welding engineer, M/s ISGEC HEAVY ENGINEERING LTD, INDIA.Ed, I just viewed the pictures of your pulsed MIG cladding technique with inconel 625 over carbon steel water wall tubes. My company is a major boiler manufacturer here in India and we have installed more than 550 power boilers in more than 30 countries.

We will be working on a project where we will be cladding INCONEL 625 over water wall panel tubes. Initially we thought of doing it with manual pulsed arc MIG, vertical down by hand, but after viewing your superb finish and the minimum dilution method, I couldn’t resist to write it to you. We are very much impressed with your MIG process control expertise and your pioneer knowledge of the subject. We will be very much grateful, if you’ll be able to spare some time to chat with us.

Ed also provided unique modified MIG Short Circuit Water Wall Clad Welds in the 1980's.

In the 1980s, twenty years before the development of decent pulsed MIG equipment, Ed produced the Inconel 622 MIG clad weld shown in the left photo (cross section of a boiler tube). In his clad weld there was no metallurgical evidence of a heat affected zone as evidence in the macro.

In contrast with the photo on right, we have the typical MIG clad weld fusion profiles that the power industry and it's water wall boilers are accustomed to producing in the 21 st Century.

The modified short circuit Inconel clad weld shown on the LEFT macro was made by Ed and his buddy Zugy in the 1980s without any cooling medium and made with a modified short circuit MIG power source and process that was first developed in 1963. The clad weld on the right is the usual poor quality MIG cladd weld with far too much weld dilution. Notice with Ed's 1980s clad weld that the lowest possible cladd weld dilution and lack of a visable HAZ was attained, something that most weld shops 40 years later in 2020 would have a difficult time duplicatiing, even with the use of the most sophisticated electronic pulsed MIG equipment.

When you look at your clad welds in 2020, note with Alloy 622 my unique modofied Short Circuit Clad Weld made 198o.

This is a result of weld process control - best weld practice expertise.

This 622 MIG Cladd... I doubt few companies with their twenty first Century, sophisticated, electronic MIG equipment could achieve a clad weld of this weld quality without a visable heat affected zone. My macro even surprised the Foster Wheeler senior metallurgist who examined it, as it was the first time he had witnessed a clad weld in which their was no virtually no evidence of any 622 alloy weld dilution with the carbon steel base alloy, and also little evidence of the clad weld HAZ.

Today in 2020 we have three D printers to produce weld castings, but back in 1980 with MIG process control expertise I was also producing Weld Castings.

.

WITHOUT MIG EQUIPMENT BELLS AND WHISTLES, IN THE 1980s, MY BUDDY ZUGY AND I PRODUCED SOME REMARKABLE ALLOY WELDED PARTS:

We never had MIG electronic equipment bells and whistles in the 1980s, yet we did have weld process expertise and low cost MIG weld equipment that was developed in the 1960s. In those days we were producing welds that are still are not produced 30 years later. In 1980 if you wanted a small vessel made from aluminum bronze you ordered a solid bar stock and spent many hours ID and OD machining, or you had it cast at a foundry and waited 6 months to a year. Of course you could have or called me and I would show you how with a few pounds on Alum Bronze 0.045 MIG weld wire, in a few hours you could make the part strictly out of weld metal as shown on the left.

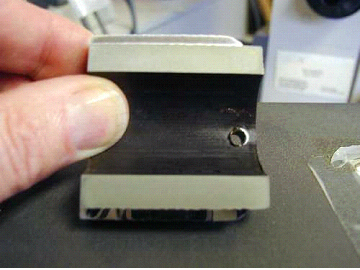

If you needed a small vessel comprised of two different alloys such as the machined piece show above middle, With this part the customer want one half made out of Hastelloy and the other half made out of 316 stainless. With the Hastelloy - Stainless part, you could have spent weeks figuring out how to make it and a small fortune in machining, or you could have called myself or Zugy and in less than a day the product would have been made from Hastelloy and stainless MIG weld wire. Yes of course these parts would pass any X-Ray evaluation.

Of course if you really wanted to impress someone in the 1980s you woul produce the holy grail of welding. Ed and Zugy took some scrap Titanium weld wire, and in three hours made the above chalice (right) a part yet again free of defects.

Cladding and Hydro-Processing Vessels

2006: 347 Another common global clad application overlay application influenced by Ed:

TYPICAL... Electro Slag Strip Electrode Process applying ER 347 clad welds.

Above a common Electro Slag Weld common Application. In the refinery industry, pressure vessels used in high temperature, high pressure "hydrogen service" such as hydrocracking and hydrotreating are usually constructed of Chrome / Molly or Vanadium modified Chrome / Moly steels. To overcome corrosion areas with these vessels, clad welds of ER 347 alloy are typically applied to plate or to wasted areas on pressure vessels.

The most common, global cladding "process" utilized for plate cladding used for hydrogen service, has been the Electro Slag Welding (ESW). This process uses strip electrodes two to three inches wide. On some applications a butter layer of ER 309 is requested followed by a surface layer of ER 347 for the clad surface. On other applications a single layer of ER 347 is applied.

With the ESW process, high deposition welds result from weld current > 600 amps. The ESW process has been considered unique in that the large size of the strip electrode results in low weld current density resulting in "low weld dilution". The down side of th ESW clad process is;

[a] The ESW is a "single" electrode process,

[b] ESW requires a large equipment package, it's cumbersome and weld position restricted,

[c] the cost of the ESW clad consumables and fluxes are high,

[d] there are few companies with ESW expertise.

[F] Many North American vessels are ESW clad in Japan.

Utilizing a unique MIG weld wire found by Ed, and cladding equipment developed by WSI, Ed produced "single pass", MIG layer clad 347 welds that met the hydrogen service 347 clad thickness, chemistry and ferrite requirements. In comparison to the ESW and SAW process, thanks to the large differences in consumable costs and the multi MIG gun capability, it's now possible in contrast to the ESW process to produce the 347 MIG clad welds, depending on the application with a 30 to 50% cost reduction.

In contrast to the much more costly ESW and SAW processes, the single pass MIG clad procedure developed by Ed and WSI enables cladding on a much wider range of applications, and allows the flexibility to provide the vessel cladding at any site locations with the vessel in any position. This weld flexability dramatically reduces the vessel lead times or shipping costs to have this clad work done.

ED'S MIG PROCESS CONTROL EXPERTISE CHANGED THIS TRADITIONAL

GLOBAL 347 ELECTRO SLAG AND SAW WELD CLAD APPLICATION.

From ESW to Ed's 347 single pass MIG clad weld.To a clad MIG process that's faster, provides less distortion, has less heat effect on the steel, costs less and is much more versatile.

Today in 2015, with some pulsed MIG equipment, we can now attain what

we were doing with weld process expertise in the 1980s.

When you have a clad welding challenges on those ID-OD power plant, refinery, and well head equipment such as ID welds on adapter flanges,bonnets, studded tees, tree caps, weld neck flanges, gate valves, please note, you can invest hundreds of thousands of dollars in sophisticated overlay equipment and never quite get that application the way it could be. You could ask a salesman for your pulsed clad MIG advice, or you could learn how to control this important process and produce clad welds without weld rework.

It

helps to have weld control process expertise.

Without question a great process for the highest quality - lowest weld heat clad welds

is from a process my business partner and I bought to the USA and Aus.

Visit the TIP TIG section of this site

This Russian found a solution to his countries poor poor automative manufacturing quality issues.

Is this a one horse power car engine? Remember if you dont have a sense of humor

and you are in the welding industry, you made a poor career choice.

My weld process control programs may be your keys to MIG weld process optimization: